Advanced Manufacturing

Add your title here

This is the text area for this paragraph. To change it, simply click and start typing. Once you've added your content, you can customize its design by using different colors, fonts, font sizes and bullets. Just highlight the words you want to design and choose from the various options in the text editing bar. This is the text area for this paragraph. To change it, simply click and start typing. After adding your content, you can customize it.

About

Triple Eight Race Engineering opened the Advanced Manufacturing facility in 2021.

We utilise specialised equipment to create bespoke engineering components for a wide variety of applications and industries.

Triple Eight Race Engineering is proudly an ISO 9001:2015 Certified Company

Triple Eight Advanced Manufacturing Capabilities

ISO-9001:2015 Quality Management System Certified

This is a paragraph. Writing in paragraphs lets visitors find what they are looking for quickly and easily.

This is a paragraph. Writing in paragraphs lets visitors find what they are looking for quickly and easily.

This is a paragraph. Writing in paragraphs lets visitors find what they are looking for quickly and easily.

This is a paragraph. Writing in paragraphs lets visitors find what they are looking for quickly and easily.

This is a paragraph. Writing in paragraphs lets visitors find what they are looking for quickly and easily.

Name Lastname

Title

Name Lastname

Title

Name Lastname

Title

CNC Machining

Our Facility houses a wide array of turning centres, mills, lathes and 5 axis machines to accurately produce quality complex components.

CNC MILLING

- HAAS VF Vertical CNC Mills

- HAAS UMC-750SS 5 Axis

- Both 3 & 5 axis capabilities

- Working Range 1000mm x 500mm

CNC TURNING

- HAAS SL-20 CNC Lathe

- HAAS ST-30y Turning Centre

- Straight and 90 degree live tooling

- Max 300 diameter x 400mm long

- 80mm diameter spindle bore

GENERAL MACHINING

- Manual Mills and Lathes

Robotic Precision Welding

State of the art robotic welding machines operate autonomously ensuring maximum production output. Consistency and accuracy are at the heart of the robotic welding operations at the Advanced Manufacturing facility.

ROBOTIC MIG WELDING

- Tru Arc Weld 1000l

- Working range 2000mm x 600mm x 600mm

MANUAL WELDING

- Precision Welding Workstations

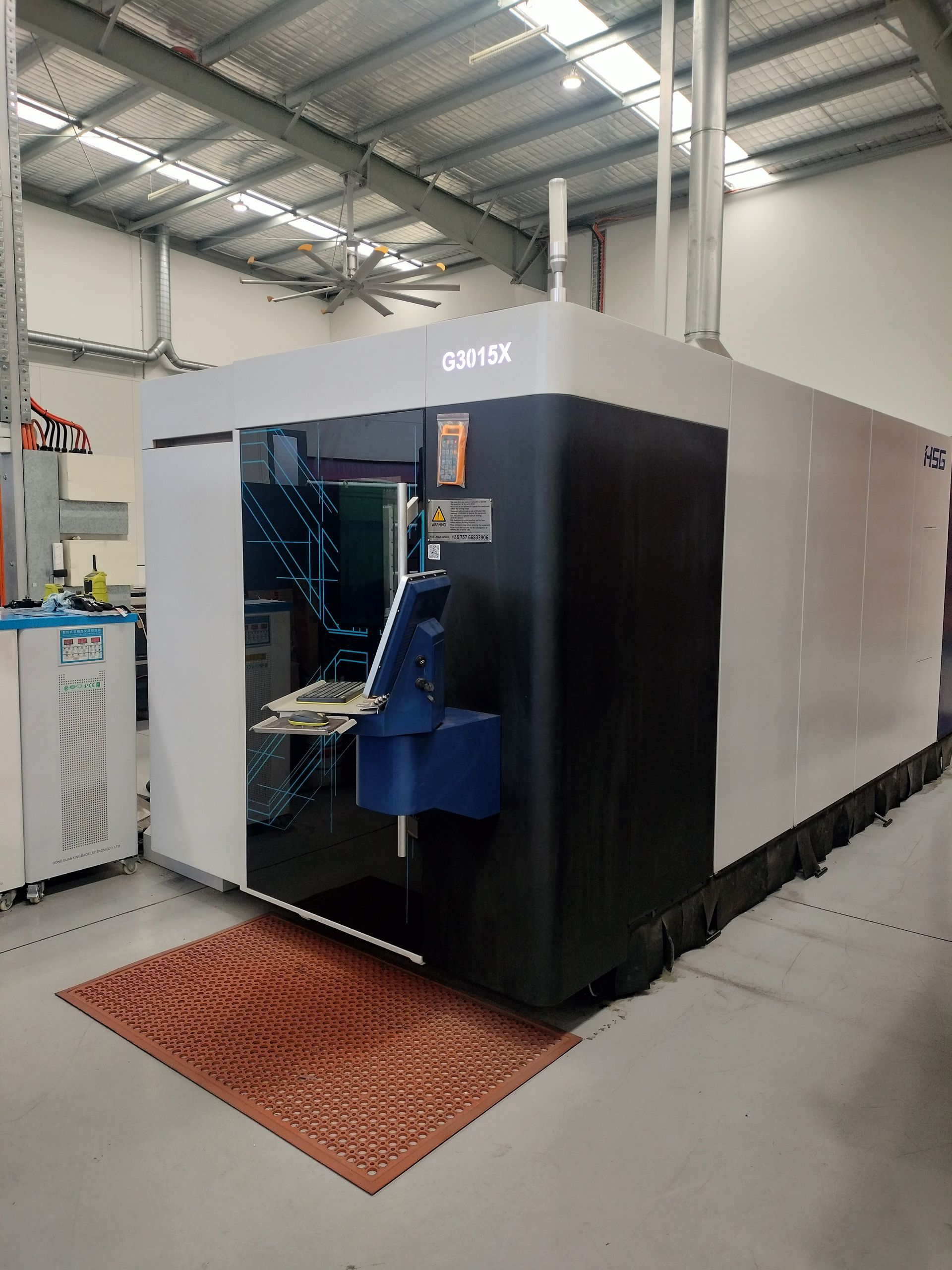

High-Tech Fabrication

Precise, high-tech CNC and laser equipment is used for all manner of operations, including a pipe-bender, 5-axies tube cutter, and laser sheet cutting machines.

FLATBED LASER CUTTING

- HSG GX Laser Cutting Machine

- Working range 3000mm x 1500mm

- Max. thickness 16mm mild steel

- 10mm Stainless steel

- 10mm aluminium

TUBE LASER CUTTING

- HSG TP65 5-axis Fibre Laser Tube-Cutter

- Up to 200mm diameter x 7.3 metre raw material length

- Max. thickness 8mm mild steel

- 6mm stainless steel and 6mm aluminium

CNC PRESSBRAKE

- CNC Press-brake Folding / Bending Machine

- 2500mm long x 80 tonne capacity – various tooling

CNC TUBE MANDREL BENDING

- YLM CNC Pipe / Tube Bender

- up to 3 inch capacity – various tool sets

Rapid Prototyping and Scanning

Rapid prototyping and plastic printing are essential tools to help aide the design and manufacturing process. Our Advanced Manufacturing facility can prototype designs before they are put into production. We also having 3D scanning capability to analyse, compare and reverse engineer components.

RAPID PROTOTYPING AND PRINTING

- Markforged

- HP

3D SCANNING

- ZEISS T-SCAN Hawk 2